We’ve Been Using Concrete Since Roman Times And Before. So We Know That Good Quality Sustainable Concrete Lasts For Millenia And Is A Building Material That Has Many Benefits.

But concrete is not without problems. Concrete is in crisis in the UK for many reasons. Concrete sickness, spalling, scaling, discolouration, crazing, efflorescence, blistering and permeability are just a few of its potential issues. It also has a negative reputation around the amount of energy used to make it and the CO2 produced in its manufacture.

However, we shouldn’t be discouraged by this. If the Romans could make it so sustainable that it has lasted thousands of years, then it has many merits. As for the embedded energy used in its manufacture, science and building technology are finding ways to significantly reduce concrete’s energy signature to the extent that it is an answer to many construction problems.

Let’s dig a little deeper and examine concrete in more detail, starting with what is concrete.

What is Concrete?

Concrete is a composite material composed of aggregate bonded together with a fluid cement that cures to a solid over time. It’s a versatile and durable material, widely used in construction due to its strength and moldability. Typically, concrete is made by mixing cement, water, and aggregates such as sand and gravel.

A Versatile Building Material with a Complex Legacy

Concrete is a ubiquitous material in modern construction, and boasts a rich history dating back millenia. Today engineering and architectural professionals are revolutionising concrete to make it even better.

Egyptian concrete included straw and mud in its mix, and wasn’t very strong. However some of it still survives.

Roman concrete included an ingredient called “pozzolana,”. Pozzolana is derived from volcanic material and it gives great strength and durability to the concrete. It also gives us clues about how to improve today’s materials.

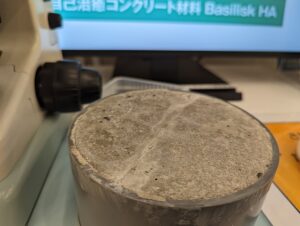

Concrete’s versatility, durability, and affordability have made it an indispensable component of countless structures. Today we even have self healing concrete (shown being laboratory tested in the photo). However, the environmental implications of modern concrete production and its thermal properties have raised concerns about its sustainability.

The Environmental Footprint of Concrete

The production of cement, the primary ingredient in concrete, is an energy-intensive process contributing significantly to greenhouse gas emissions. Furthermore, concrete’s low thermal conductivity often leads to energy-inefficient buildings with high heating and cooling demands.

Innovations in Sustainable Concrete

Recognising the need for more sustainable building materials, the construction industry is actively exploring innovative approaches to reduce concrete’s environmental impact.

Recycled Aggregates and Alternative Cements

Incorporating recycled concrete aggregates into new concrete mixtures can divert waste from landfills and conserve natural resources. Additionally, the development of low-carbon cements, such as geopolymer cement, offers a promising alternative to traditional Portland cement.

Enhancing Thermal Performance

Improving concrete’s thermal properties is crucial for energy efficiency. Incorporating insulation within concrete walls or utilising concrete with enhanced thermal conductivity can significantly reduce energy consumption. Moreover, advanced cooling technologies integrated into concrete structures can enhance indoor comfort while minimising energy use.

A Sustainable Future for Concrete

While concrete presents environmental challenges, ongoing research and development are paving the way for a more sustainable future. By adopting innovative practices and technologies, we can harness the benefits of concrete while minimising its environmental footprint. The construction industry’s commitment to sustainability is essential in transforming concrete from a potential villain into a cornerstone of a greener, more resilient built environment.

Reinventing Cement & Concrete.

The cement industry is a major contributor to global carbon dioxide emissions. Traditional cement production involves heating limestone in a kiln at extremely high temperatures, releasing significant amounts of CO2. Recognising the urgent need to reduce this environmental impact, companies are developing innovative solutions.

Several companies are pioneering new methods to decarbonise the cement industry. In many of these methods CO2 is captured during the process, making concrete part of the CO2 solution. Here are just a few of the ways concrete is being further developed.

- Technologists are developing a cement that uses a higher proportion of sand, reducing energy consumption and capturing CO2 during the curing process.

- Another technology injects captured CO2 into concrete, enhancing the material’s strength while significantly reducing its carbon footprint.

- Many opportunities exist to replace traditional cement with ground steel slag, curing the concrete with CO2 and eliminating the need for high-carbon Portland cement.

- Concrete technologists are also exploring an electrochemical process to produce cement at ambient temperature, dramatically reducing energy consumption and associated carbon emissions.

- Some concrete production is now focusing on using calcium-rich rocks instead of limestone, bypassing the CO2-releasing step in traditional cement production.

These innovative approaches represent significant strides towards a lower-carbon cement industry. We have to recognise that we haven’t totally cracked the concrete problem yet but we are making strides in the right direction.

But there’s more that architectural professionals can do.

Decarbonise Concrete Use in Construction

Beyond the innovative cement production methods discussed, architectural professionals and builders can significantly reduce concrete’s carbon footprint through design and construction practices.

Design Strategies

- Optimise concrete use: Minimise concrete volumes through efficient structural design and material substitution where possible.

- Embodied carbon assessment: Evaluate the total carbon impact of building materials, including concrete, to make informed design decisions.

- Circular economy principles: Design buildings for disassembly and reuse of concrete components.

- Material efficiency: Utilise concrete with lower cement content while maintaining structural integrity.

- Alternative materials: Explore and incorporate alternative building materials such as timber, steel, or recycled materials where feasible.

Construction Practices

- Concrete recycling: Reuse demolished concrete as aggregate in new concrete mixes.

- Low-carbon concrete: Specify concrete mixes with lower embodied carbon through the use of supplementary cementitious materials (SCMs) such as fly ash and slag.

- Concrete curing: Optimise curing processes to reduce water consumption and carbon emissions.

- Construction waste management: Minimise concrete waste through careful planning and execution.

- Digitalisation: Employ advanced technologies such as Building Information Modeling (BIM) to optimise material use and reduce waste.

Training

- Technology and science advance hand in hand and at a rapid pace. So architectural professionals need to keep pace with that change. There are many ways of doing this and we are constantly reviewing our needs and the additional training available from organisations such as RICS, (Royal Institution of Chartered Surveyors) which run professional courses such as their modules on the Whole Life Carbon Assessment standard, which covers concrete and more.

Complying with Building Control & Customer Requirements

Concrete technology is evolving. But this alone isn’t enough. At all times it has to meet the strict criteria imposed by both regulation and the customers that buy it.

Concrete needs to meet, or preferably exceed, building control criteria. And that makes sense because building control is concerned with ensuring buildings are constructed in accordance with building regulations. The regulations are minimum standards for ensuring buildings are safe, inclusive environments for people to live and work in.

And from a customer perspective the concrete has not only to meet building control standards, it also has to meet aesthetic andt sustainability standards and be affordable.

Concrete Conclusions

By adopting these strategies, architectural professionals, engineering professionals and builders can significantly contribute to reducing the carbon footprint of concrete in the construction industry, thus also reducing materials and cost.

Are you interested in reducing the carbon footprint of your building project? We would be happy to work with you, starting with a chat over coffee.

You Can Contact Us For Any Informal Chat Anytime

Phone 074439 07933

or email jack@swellarchitecture.com

More Articles On Sustainable Architecture Are Being Added Regularly & Can Be found by Following The Link